Introduction

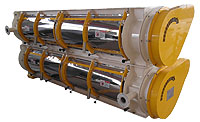

We adopt the most advanced Italy technology, and the equipment can be customized.Double paddle feed mixer is a kind of horizontal mixing device with high efficiency, high uniformity, high intensity, low energy consumption and low pollution.

Usage

Provide Customized Production According To Customers’ Demand.It’s used for uniform mixing of different ingredients in a shortest time (CV< 5%) regardless of density, shape and size. And the mixing time is 60-90s.

Application

The double paddle mixer is widely used for mixing powder-powder and powder-granule, particularly suitable for materials with big difference in specific gravity or particle size in industries such as food, feedstuff, chemical, fertilizer, etc.

- Consult equipment, ask for quotation

- Tel:0086-0371-53762053

Pellet Making Machine Technical Advantage

Insist on technical innovation to meet market requirement of current scale, energy saving and environmental protection

-

1 Working Process

The pitched paddles moves material from the bottom, and forces the material back down between shafts, giving a complete and uniform mixture of materials.

-

2 Design

The design for double paddle feed mixer is based on a U-type tank, with dual shafts and double paddles extending the length of the tank.

-

3Discharging Ways

There are three ways for materials discharging: manual operation, motor-drive and pneumatic discharging methods.

-

4No Leakage

It is equipped with air return duct to ensure no powder leakage and protect working environment. And the material discharging is quick.

-

5 Atomizing Nozzle

Atomizing nozzle can be customized according to your demands, if you have needs to add molasses, oils & fats and other liquids.

-

6 Shaft & Discharge door Sealing

Shaft seal uses unique sealing technology, reliable sealing, no leakage, long service life. Discharge door seal uses molded sealing strip.

Parameter Specification

Both of process design and late return, Yuxi Pellet Making Machine is your best choice!

| Model | Effective Volume

(m3) |

Dimension(mm) | Mixing Volume

(kg/bat) |

Power

(kw) |

Loading Coefficient | Variation Coefficient (%) |

| YX-1A | 1 | 2730×1383×2000 | 500 | 11/15 | 0.4~0.9 | ≤5 |

| YX-2A | 2 | 3186×1717×2490 | 1000 | 18.5/22 | 0.4~0.9 | ≤5 |

| YX-4A | 4 | 3859×2249×2812 | 2000 | 37/45 | 0.4~0.9 | ≤5 |

| YX-6A | 6 | / | 3000 | 55 | 0.4~0.9 | ≤5 |

Focus On Pellet Machine With 21 Year, Feel Free To Contact Us!

![]()

- Yuxi Machine service includes: reach the desired output, product quality meet the requirements, each consumption indicators meet the requirements, effectively control the cost of production, process equipment can stable operation.

Production capacity achieve indicators, the expected economic benefits to achieve, product quality can meet the requirements, etc