Introduction

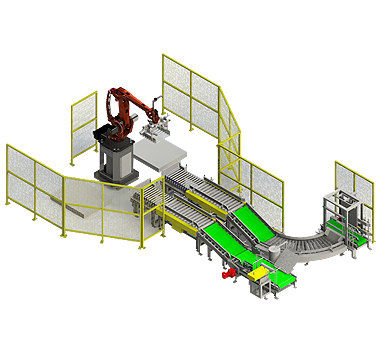

We adopt the most advanced Italy technology, and the equipment can be customized.With different grabs, intelligent palletizing robot can be used for packing and stacking of finished products with different shapes in different industries.

Staclomg Form

Provide Customized Production According To Customers’ Demand.The palletizing robot can flexibly deal with different stacking demands and non-standard stacking forms, designed according to users’ requirements.

Application

Palletizing robots are widely used for palletizing bag, boxe and barrel products in the feed industry, fertilizer industry, flour industry, cement industry, beer industry, grain and oil industry, seasoning industry, daily chemical industry, etc.

- Consult equipment, ask for quotation

- Tel:0086-0371-53762053

Pellet Making Machine Technical Advantage

Insist on technical innovation to meet market requirement of current scale, energy saving and environmental protection

-

1 Sturcture

This palletizing robot consists of two system: controller system and manipulator system, gripper can be customized to match different industries.

-

2 Modularize Design

Mechanical structure adopts modular design to improve the versatility of parts, easy maintenance, improve equipment machining accuracy.

-

3Spare Parts

As its structure is simple and the spare parts are few, the fault rate of spare parts is low, and the required stock spare parts are less.

-

4Small Occupation

The robot occupies less space, which is useful for the clients’ production line layout, and the warehouse space can also be increased.

-

5 Strong Feasibility

When the product size, volume, shape or the pallet dimension changes, you can revise it by touch screen without affecting the normal production.

-

6 Energy Saving

The driven power for mechanical palletizing machine is much higher that for palletizing robot, greatly reduce the operation cost.

Parameter Specification

Both of process design and late return, Yuxi Pellet Making Machine is your best choice!

| Item | Specification | |||

| YX-120 | YX-200 | YX-300 | ||

| Controlled Axis | 4 Ases (A.B.C.D) | |||

| Installation | Floor Mount | |||

| Max.Load Capacity (including the grab) (kg) | 120 | 200 | 300 | |

| Handing Capacity(kg) | 1400 | 1600 | 1000 | |

| Motion Range | A(left-right) | 330° | 330° | 330° |

| B(up-down) | 2000mm | 2300mm | 2300mm | |

| C(front-back) | 1300mm | 1500mm | 1500mm | |

| D(grab) | 330° | 330° | 330° | |

| Drive Method | Electric Servo Drive by AC Servo Motor | |||

| Positional Repeatability | ±0.5mm | |||

| Power Consumption(kw) | 4 | 9.6 | 11.5 | |

| Weight(kg) | 750 | 1100 | 1500 | |

| Installation Condition | Ambient Temperature -10 – 45°C | |||

| Ambient Humidity 85%RH | ||||

Focus On Pellet Machine With 21 Year, Feel Free To Contact Us!

![]()

- Yuxi Machine service includes: reach the desired output, product quality meet the requirements, each consumption indicators meet the requirements, effectively control the cost of production, process equipment can stable operation.

Production capacity achieve indicators, the expected economic benefits to achieve, product quality can meet the requirements, etc