Introduction

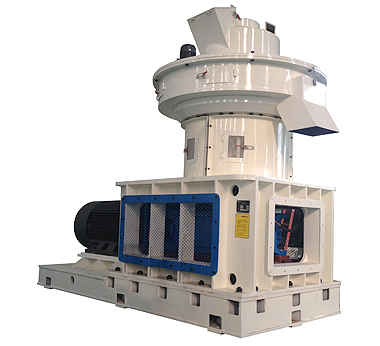

We adopt the most advanced Italy technology, and the equipment can be customized.After eucalyptus wood, pine, birch, fruit tree, crops straw and bamboo sawdust crushed to sawdust, wood pellet machine can process them into biomass fuel.

Mold

Provide Customized Production According To Customers’ Demand.● The mold is vertical. Vertical feeding, no arch camber, easy for heat dissipation;

● The mold is stationary vertical installation, easy to be fixed, running smoothly;

Vertical Ring Die

Vertical ring die wood pellet maker can effectively overcome to the difficult granulation of biological crude fiber. The host drives with efficient belt, ring die adopts the quick release hoop type, feeding uses frequency control.

- Consult equipment, ask for quotation

- Tel:0086-0371-53762053

Pellet Making Machine Technical Advantage

Insist on technical innovation to meet market requirement of current scale, energy saving and environmental protection

-

1 Pressure Wheel

The pressure wheel of the wood pellet mill rotates to help the material produce a centrifugal force, evenly distributed around.

-

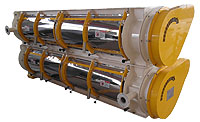

2 Shaft

The main shaft and hollow shaft adopt alloy constructional steel imported from Germany, with reasonable structure, uniform hardness.

-

3Uniform Hardness

The uniform hardness of the shafts improves the fatigue resistance and wear resistance, safety operation to provide more reliable protection.

-

4Bearings

Bearings of particle formation system are made of high-quality silent bearings, increasing thin oil circulation cooling and lubrication systems.

-

5 Transmission Parts

Transmission parts use imported Japan high-precision bearings and the United States imported wear-resistant and heat-resistant fluorine rubber seal.

-

6Oil Lubrication

The addition of lubricating oil return systems, oil circulation cooling, automatic timing for oil lubrication to ensure adequate lubrication of bearings.

Parameter Specification

Both of process design and late return, Yuxi Pellet Making Machine is your best choice!

| Model | Power

(kw) |

Pellet Size

(mm) |

Inner Diameter Of Circular Mould

(mm) |

Capacity(t/h) | Dimension

(mm) |

Weight(t) |

| YX-450 | 55+1.5+0.37+1.5 | 4-12 | 450 | 0.7-1 | 2300*1100*2100 | 4.5 |

| YX-560 | 90+1.5+0.37+1.5 | 4-12 | 560 | 1—1.5 | 2600*1300*2300 | 5.8 |

| YX-680 | 160+1.5+0.37+1.5 | 4-12 | 680 | 1.5—2.5 | 2900*1300*2400 | 6.5 |

Focus On Pellet Machine With 21 Year, Feel Free To Contact Us!

![]()

- Yuxi Machine service includes: reach the desired output, product quality meet the requirements, each consumption indicators meet the requirements, effectively control the cost of production, process equipment can stable operation.

Production capacity achieve indicators, the expected economic benefits to achieve, product quality can meet the requirements, etc