Introduction

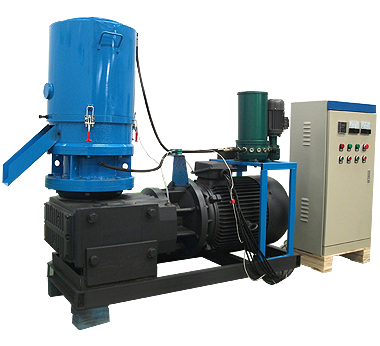

We adopt the most advanced Italy technology, and the equipment can be customized.Small feed pellet mill is mainly used for small scale production of animal and poultry feed pellets, grain feed factory, farm, poultry farm, etc.

Application

Provide Customized Production According To Customers’ Demand.Small animal feed pellet machine is used for processing various kinds of solid grain into small feed pellets for animals, such as cattle, cow, chicken, rabbit, pig.

Structure

Small animal feed pellet making machine uses flat die pelleting equipment, and it’s mainly composed of severial parts, such as motor, gearbox, drive shaft, mold plate, pressure roller, feed hopper, cutter and outlet hopper.

- Consult equipment, ask for quotation

- Tel:0086-0371-53762053

Pellet Making Machine Technical Advantage

Insist on technical innovation to meet market requirement of current scale, energy saving and environmental protection

-

1 Advantage

The small poultry feed making machine has the unique advantages of simple structure, small area coverage, competitive price and low consumption.

-

2 Wear-Resistant Material

The small poultry feed machine is made of wear-resistant material, which can ensure it has a long service life.

-

3Simple Structure

With simple structure design of the small feed pellet mill, its maintenance and repair is absolutely more convenient and much simpler.

-

4Raw Material

The raw materials can be corn, maize, wheat bran, rice, beans, etc., which are easy to obtain, with energy-saving and environmental friendly.

-

5 Gearbox

Adopt the SKJ series new generation gearbox, driven by high-precision gears, automanic lubricant pump system, ensuring stable operation and service life.

-

6Transmission

The whole transmission part uses high-quality bearings and seals, making sure that the transmission is efficiency, stability, and low noise.

Parameter Specification

Both of process design and late return, Yuxi Pellet Making Machine is your best choice!

| Model | Power(Kw) | Capacity(Kg/h) | Weight(Kg) | Dimension(mm) |

| YX-120 | Triphase 3/Uniphase 2.2 | 60-100 | 80/100 | 750*320*680 |

| YX-150 | Triphase 4 | 90-120 | 95/110 | 800*450*700 |

| YX-200 | Triphase 7.5 | 200-300 | 200/230 | 1050*480*930 |

| YX-230 | Triphase 11 | 300-400 | 290/320 | 1180*540*1000 |

| YX-260 | Triphase 15 | 400-600 | 320/360 | 1240*540*1000 |

| YX-300 | Triphase 22 | 600-800 | 410/450 | 1300*560*1100 |

| YX-550 | Triphase 55 | 800-1000 | 2000 | 2300*750*1850 |

| Model | Power(Kw) | Capacity(Kg/h) | Weight(Kg) | Dimension(mm) |

| YX-150C | Triphase 4 | 90-120 | 105/125 | 1000*480*780 |

| YX-200C | Triphase 7.5 | 200-300 | 210/230 | 1050*550*830 |

| YX-230C | Triphase 11 | 300-400 | 290/320 | 1200*560*950 |

| YX-260C | Triphase 15 | 400-600 | 340/370 | 1240*580*1000 |

| YX-300C | Triphase 22 | 600-800 | 425/465 | 1300*620*1100 |

Focus On Pellet Machine With 21 Year, Feel Free To Contact Us!

![]()

- Yuxi Machine service includes: reach the desired output, product quality meet the requirements, each consumption indicators meet the requirements, effectively control the cost of production, process equipment can stable operation.

Production capacity achieve indicators, the expected economic benefits to achieve, product quality can meet the requirements, etc