Introduction

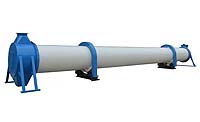

We adopt the most advanced Italy technology, and the equipment can be customized.Drum dryer is of strong adaptability to materials and can be used to dry all kinds of materials, with simple and reliable operation.

Application

Provide Customized Production According To Customers’ Demand.Drum dryer is used widely in various industries, and the color and shape of final product is very good. When drying, it keeps smooth and can dry material very fast.

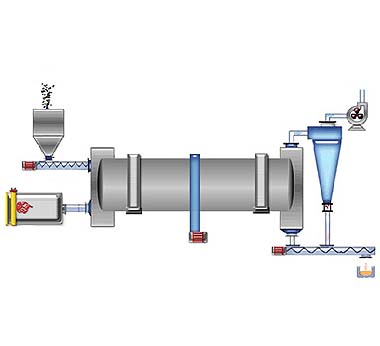

Working Principle

The hot air move forward from tail of the drum dryer, fully contact with the materials, and then fully utilize the heat by heat conduction, convection, radiation heat transfer. The material moisture constantly evaporated in the cylinder by using the heat.

- Consult equipment, ask for quotation

- Tel:0086-0371-53762053

Pellet Making Machine Technical Advantage

Insist on technical innovation to meet market requirement of current scale, energy saving and environmental protection

-

1 Draft Fan

The draft fan at feeding inlet pump out a lot of moisture and wet air stream, preventing the secondary pollution caused by dust discharging.

-

2 Large Intensity Of Drying

Because the material highly dispersed in the gas stream, the entire surface of the particles is effective drying area.

-

3Thermal Efficiency

Short drying time, large capacity, high thermal efficiency. When drying unbound water, thermal efficiency is up to 60%.

-

4Advantage

It has many advantages such as sample and reliable operation, excellent dust prevention, good sealing effect and convenient maintenance.

-

5Zero Thrust

The rotary dryer realizes “zero thrust”, greatly reducing wear of riding wheel and catch wheel, cylinder with smooth and reliable operation.

-

6Self-Aligning

The dryer “self-aligning type riding wheel device”, so the riding wheel and rolling ring can be linear contact to reduce the wear and power loss

Parameter Specification

Both of process design and late return, Yuxi Pellet Making Machine is your best choice!

| Model | Cylinder Inner Diameter

(mm) |

Cylinder Length

(mm) |

Rotation Rate | Motor Power(kw) | Inlet Temperature | Exit Temperature | Weight

(T) |

| YX-Φ0.8*12m | 800 | 12000 | 10 | 5.5 |

400-600℃ |

60-90℃ |

3 |

| YX-Φ1.0*12m | 1000 | 12000 | 10 | 7.5 | 3.5 | ||

| YX-Φ1.2*12m | 1200 | 12000 | 8 | 7.5 | 4.2 | ||

| YX-Φ1.4*12m | 1400 | 12000 | 6 | 7.5 | 4.8 | ||

| YX-Φ1.5*12m | 1500 | 12000 | 5 | 7.5 | 6.2 | ||

| YX-Φ1.6*12m | 1600 | 12000 | 5 | 7.5 | 6.8 | ||

| YX-Φ1.6*24m | 1600 | 24000 | 4 | 15 | 12.8 | ||

| YX-Φ1.8*24m | 1800 | 24000 | 4 | 11 | 7.2 | ||

| YX-Φ1.8*24m | 1800 | 24000 | 4 | 15 | 15 | ||

| YX-Φ2.0*12m | 2000 | 12000 | 4 | 11 | 15 | ||

| YX-Φ2.0*24m | 2000 | 24000 | 4 | 15 | 26 | ||

| YX-Φ2.2*12m | 2200 | 12000 | 3.5 | 18.5 | 15 | ||

| YX-Φ2.2*24m | 2200 | 24000 | 3.5 | 22 | 28 | ||

| YX-Φ2.5*12m | 2500 | 12000 | 3.5 | 18.5 | 16 | ||

| YX-Φ2.5*24m | 2500 | 24000 | 3.5 | 22 | 24 | ||

| YX-Φ2.8*12m | 2800 | 12000 | 3.5 | 30 | 17 | ||

| YX-Φ2.8*24m | 2800 | 24000 | 3.5 | 37 | 32 |

Focus On Pellet Machine With 21 Year, Feel Free To Contact Us!

![]()

- Yuxi Machine service includes: reach the desired output, product quality meet the requirements, each consumption indicators meet the requirements, effectively control the cost of production, process equipment can stable operation.

Production capacity achieve indicators, the expected economic benefits to achieve, product quality can meet the requirements, etc