Introduction

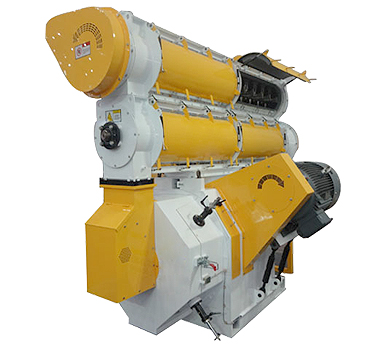

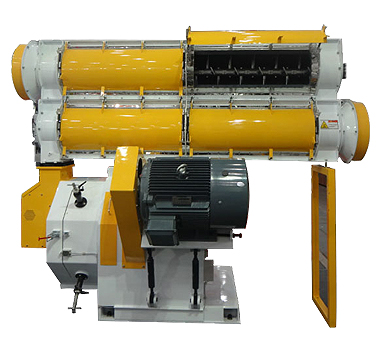

We adopt the most advanced Italy technology, and the equipment can be customized.Feed pellet mill can be divided into fish feed machine and cereal extruder, and the raw materials are easy to obtain, such as corn, maize, wheat bran, rice, beans, etc.

Application

Provide Customized Production According To Customers’ Demand.Animal feed pellet making machine is mainly used for small to medium-sized production of animal and poultry feed pellets, grain feed factory, farm, etc.

Working Principle

Animal feed pellet machine converts mechanical energy into heat energy, extruding food to make it ripe by using the heat created by rotation of the equipment. And the most obvious feature of the feed after puffing is the larger size.

- Consult equipment, ask for quotation

- Tel:0086-0371-53762053

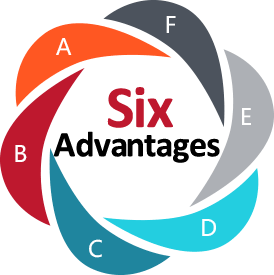

Pellet Making Machine Technical Advantage

Insist on technical innovation to meet market requirement of current scale, energy saving and environmental protection

-

1 Cutting Structure

International advanced cutting structure, use the cutter shaft & spring together cutting form, realizing stepless speed change.

-

2 Novel Design

The poultry feed making machine is with novel design, unique and simple structure, easy to install, dismantle and unload, and also easy to operate.

-

3Transmission Performance

The poultry feed machine adopts imported SKF bearings & NAK oil seals to get better transmission performance, stable operation and less noise.

-

4Screw

The screw is made from the special material, 38 CrMOALA, with wear-resistant high temperature and humidity, so it has wear resistance and long life.

-

5Pressurized Die Device

The machine is equipped with unique pressurized die device to ensure the feed; electric heating device improves the feed expansion rate.

-

6 Main Motor

The main motor adopts high quality Y series three-phase motor to ensure strong power; the reducer cooperates with it to ensure abundant power.

Parameter Specification

Both of process design and late return, Yuxi Pellet Making Machine is your best choice!

| Model | Ring Die Inner Diameter&Suppressing Zone Width | Roller Diameter

(mm) |

Power

(kw) |

Capacity

(t/h) |

Dimension (mm) |

| YX-25 | 250×75 | 104 | 2×11 | 0.4~1 | 970×1055×1069 |

| YX-35 | 350×100 | 168 | 2×30 | 3.5~5 | 1068×1119×142 |

| YX-42 | 420×138 | 204 | 2×55 | 3~12 | 1592×1589×1976 |

| YX-52 | 520×176 | 250 | 2×75 | 12~15 | 1398×1672×2103 |

Focus On Pellet Machine With 21 Year, Feel Free To Contact Us!

![]()

- Yuxi Machine service includes: reach the desired output, product quality meet the requirements, each consumption indicators meet the requirements, effectively control the cost of production, process equipment can stable operation.

Production capacity achieve indicators, the expected economic benefits to achieve, product quality can meet the requirements, etc